Ceramic Technology

Why Ceramic Armor?

A ceramic used for ballistic armor? Actually… yes. A metal is strong, but under ballistic impact it flows out of the way of the projectile like a liquid. While they fracture easily, ceramics are hard, they do not plastically deform (flow).

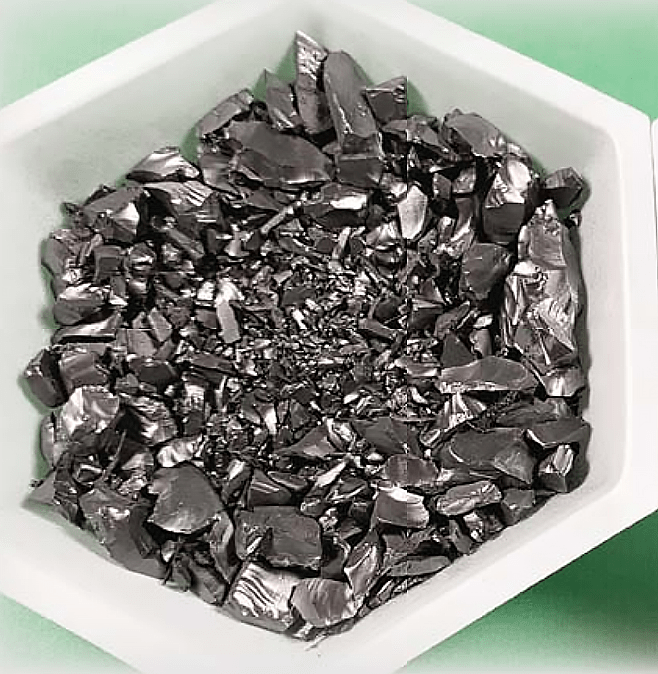

The impacting projectile is forced to dwell on the strike face surface. It collapses onto itself, mushrooming laterally. Within the ceramic, a compressive wave propagates to the back, returning as a tensile wave, pulverizing it. The projectile mass ablates away as it pushes through the abrasive rubble. Layers of polymeric ballistic fabric backing then catch the fragments.

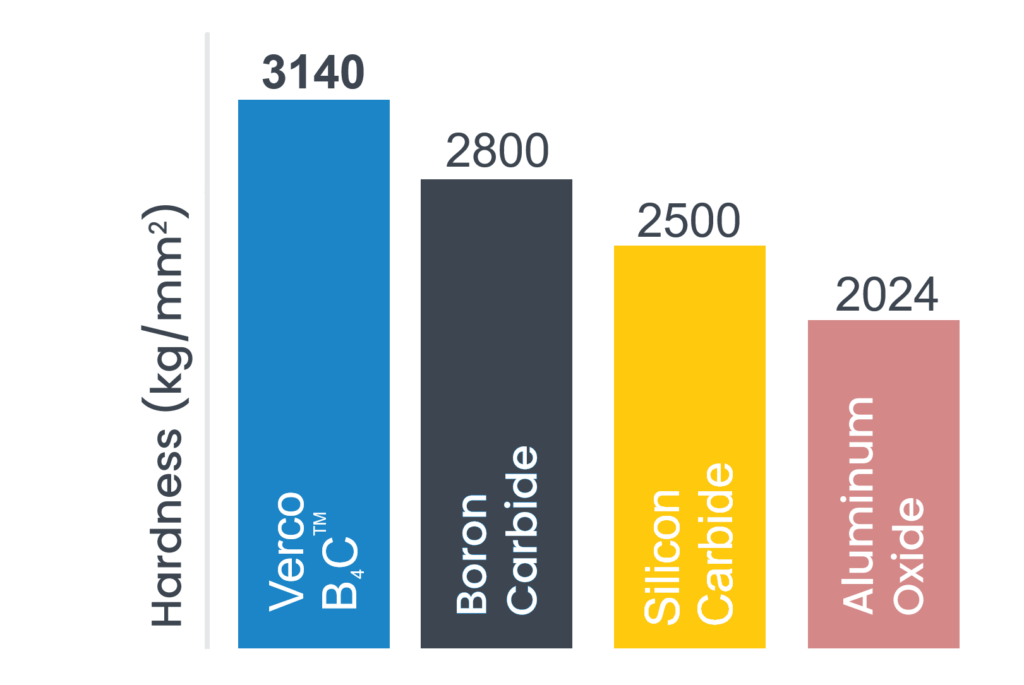

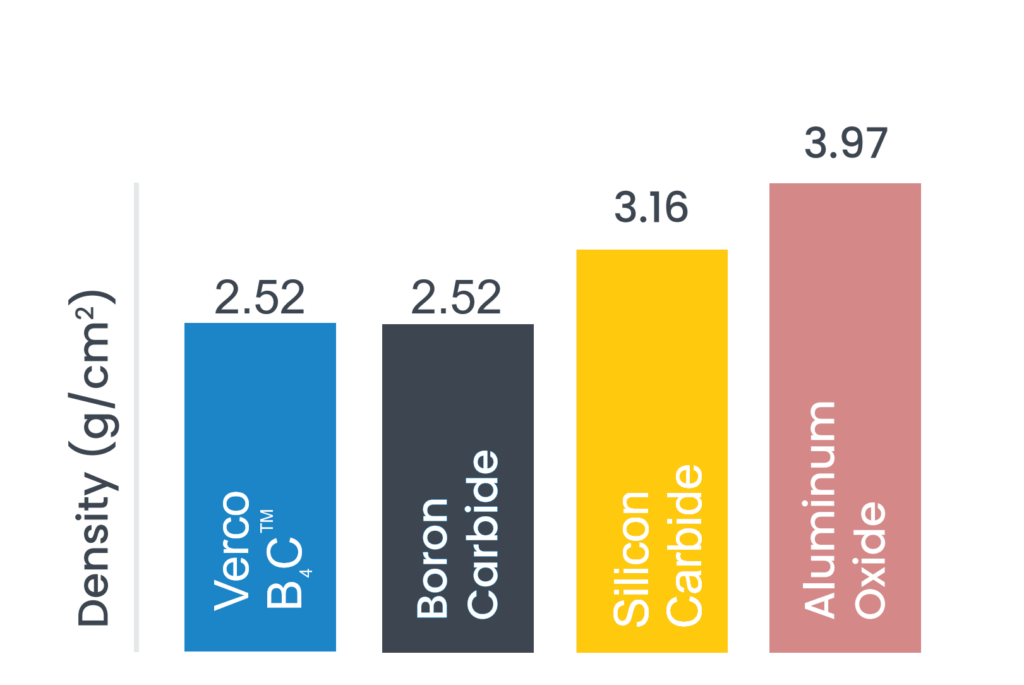

High performance ceramics used as strike face for personal armor

Boron carbide is the hardest and the lightest. It will defeat greater threats at lower weights. However, boron carbide is the most difficult to manufacture, especially in complex shapes.

Sintering Technology

Verco has developed a novel, patented, method of forming boron carbide. Powder pressed into a compact of a desired shape is sintered at very high temperatures. Atoms diffuse so that particles consolidate without ever melting. Subsequent heating under high pressure argon gas forms a pore-free, sub-micron grained microstructure of extreme hardness. This VercoB4CTM process allows for the formation of a boron carbide component, without any machining, in any desired shape.

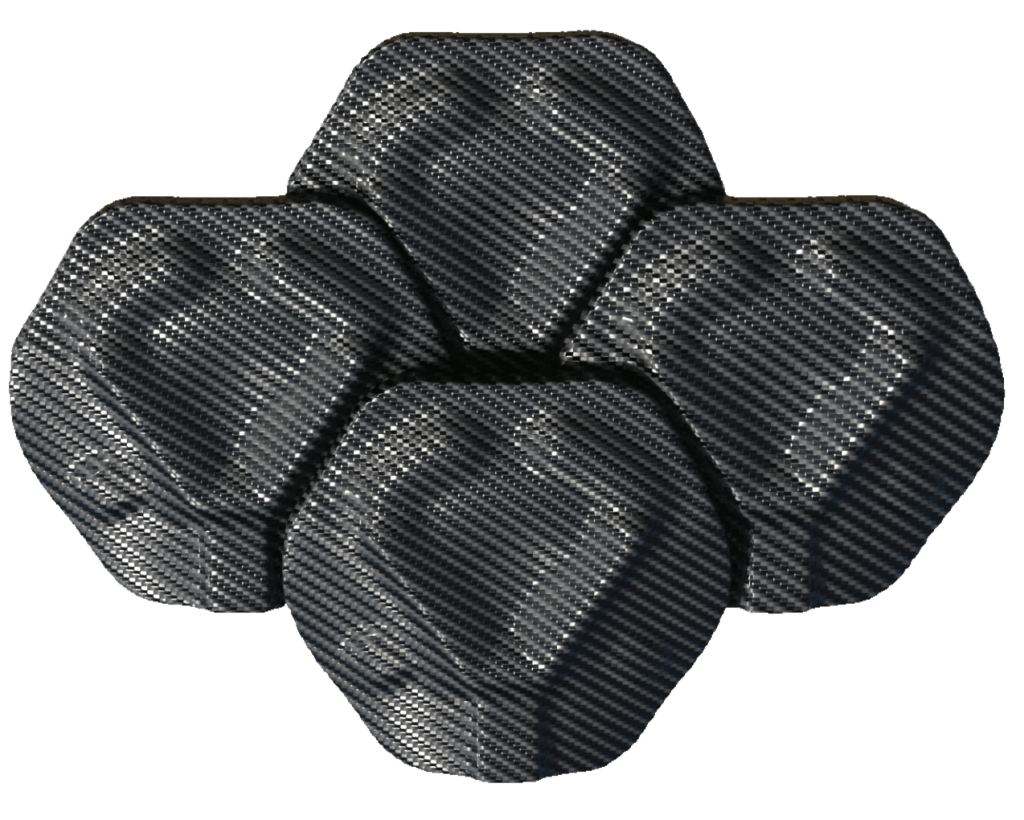

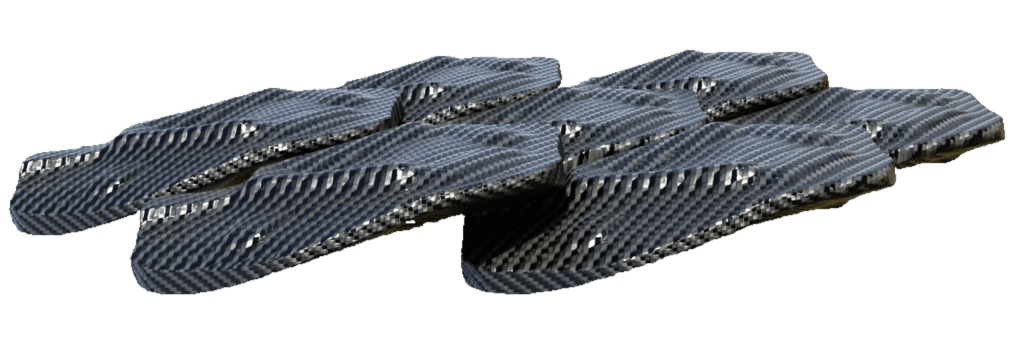

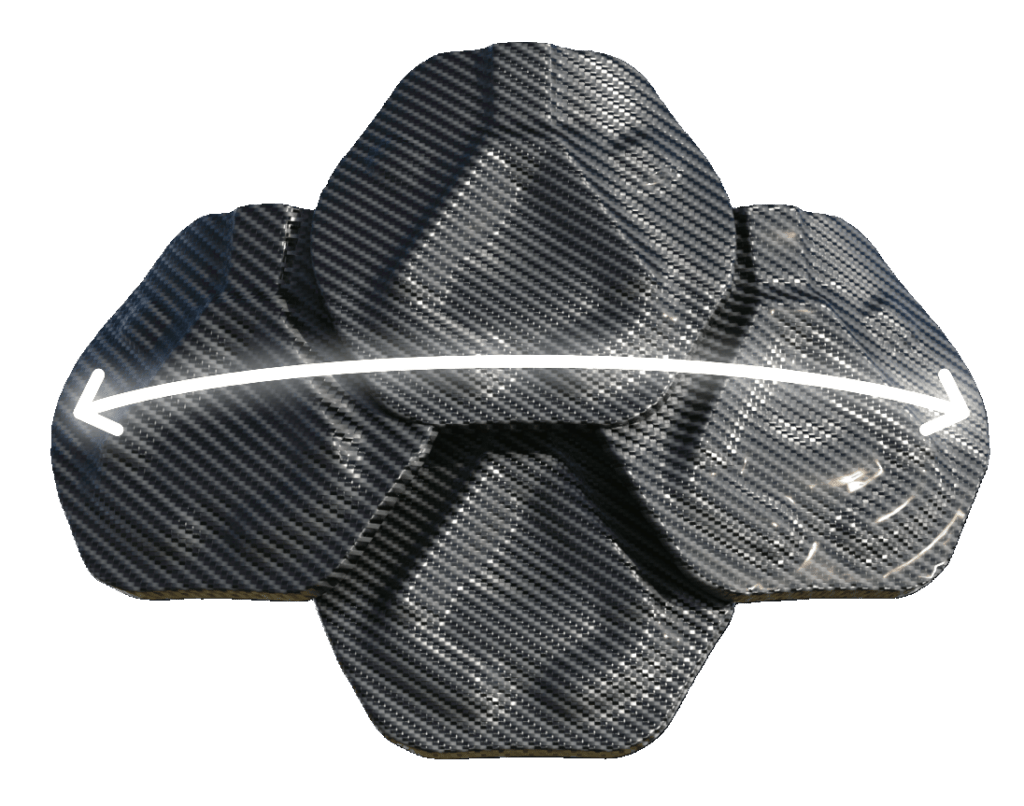

Tile Imbrication

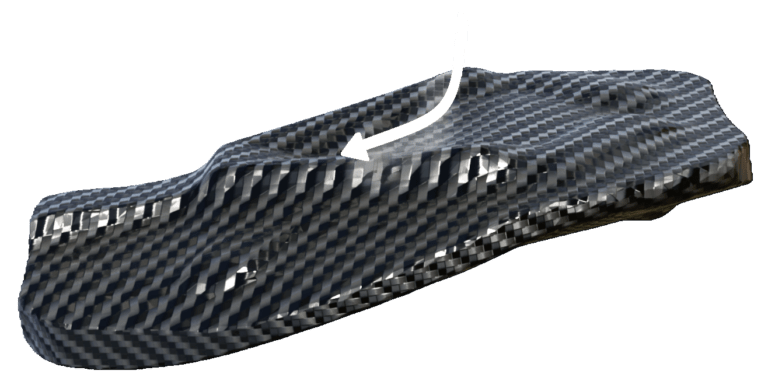

The tiles assemble so that the V feature protects what would otherwise be oblique gaps between the tiles

The four-tile oblique gap is defended by a tooth on the wear face (underside) of the upper tile mating to a well on the strike face of the lower tile.

Ceramic armor suffers a diminution in ballistic performance at near-edge regions. The patented imbrication design compensates for this; near edge regions overlap with adjacent tiles.

Rod heights indicate total tile thickness. Tile edge regions of 2- and 3-tile overlaps are thicker to compensate for edge weakening. This gives all locations of the imbrication pattern more equal ballistic performance.

Tiles rest at an angle to the body. That and surface undulations encourage projectiles to turn on impact, increasing the cross-sectional area of interaction, facilitating defeat.

Tiles rock, showing limited flex without opening oblique gaps. Over an entire panel, this imbues conformability and pliancy.

Containment

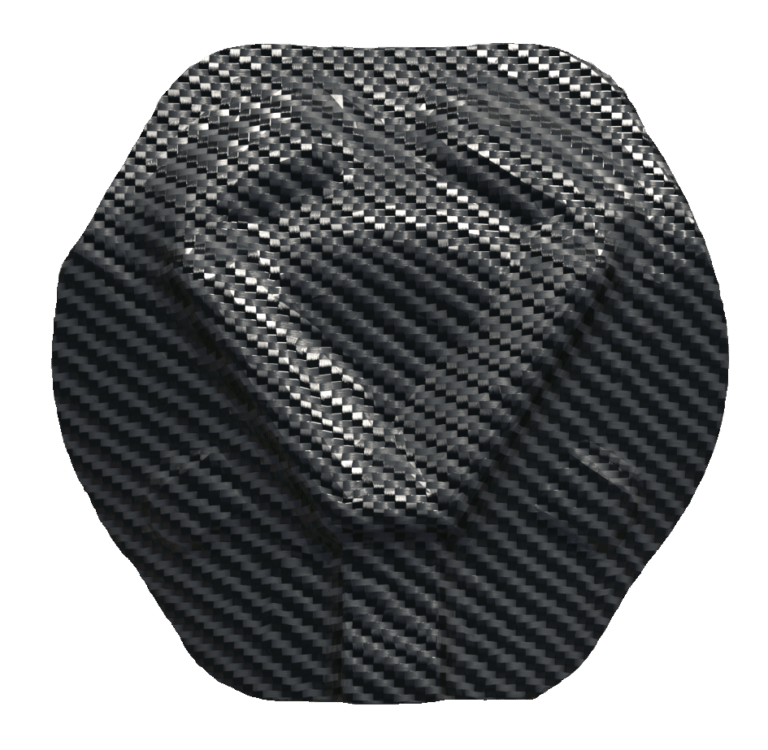

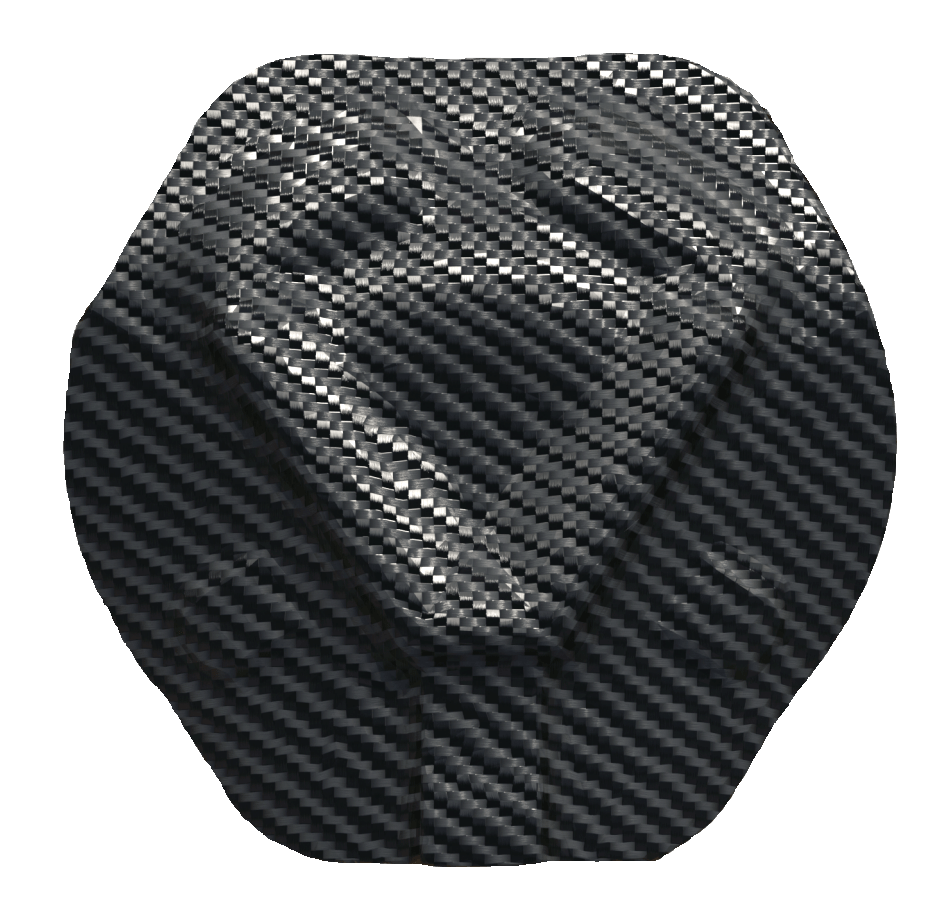

All VercoB4CTM tiles are wrapped in a patented, compressive carbon fiber weave epoxy prepreg to aid in containment of the ceramic.

VercoB4CTM Tile

VercoB4CTM Wrapped Tile

Ceramic Rubble

Single tiles center shot with M855, Oregon Ballistic Labs

With Containment

Without Containment

- This confinement enhances the tile durability against damage from rough handling.

- Constrained rubblized boron carbide impedes projectile perforation, extending dwell.

- The immobile ceramic continues to pulverize, absorbing the projectile’s energy in forming new surfaces.